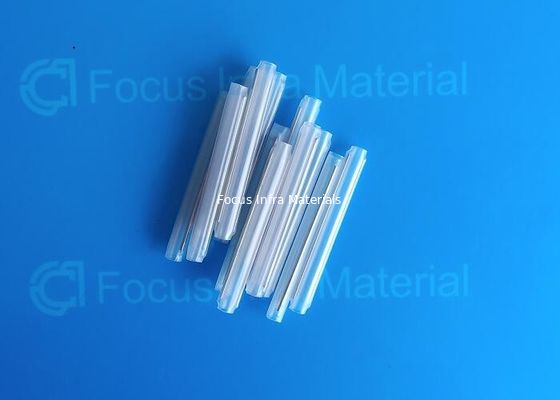

FTTH Project Fiber Optic Heat Shrink Tube 40mm Splice Sleeves

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | FTTH Project Fiber Optic Heat Shrink Tube 40mm Splice Sleeves | Use | Fiber Drop Cable Connection Protective |

|---|---|---|---|

| Brand | Focus Infra Or OEM | Material | Heat Shrink Tube, Stainless Steel Rod, Fusion Tube |

| Application | FTTH Project | Fit For | FTTH Drop Cable |

| Length | 40mm | Diamter Of Steel Rod | 1.0mm |

| Inner Diameter | 3.7mm | Steel Rod Pin | 2 |

| Color | Clear | Operating Temperation | -45°C To +120°C |

| Place Of Origin | China | Pack | 50pcs/bag Or Negotiable |

| Highlight | FTTH fiber optic heat shrink tube,FTTH 40mm Corning Splice Sleeves,40mm corning splice sleeves |

||

FTTH Project Fiber Optic Heat Shrink Tube 40mm Splice Sleeves

Description:

FTTH Project Fiber Optic Heat Shrink Tube 40mm Splice Sleeves is a protective element for outdoor or indoor cable and between indoor cable and single core fiber jumper. Focus Infra’s FTTH Project Fiber Optic Heat Shrink Tube 40mm Splice Sleeves is manufactured with pre-shrunk at both end of sleeves to keep the steel rod from dropping out. All members maintain perfect alignment during shipping, handling and shrinking. Focus Infra’s FTTH Project Fiber Optic Heat Shrink Tube 40mm Splice Sleeves has 40 mm – 60 mm are available, single steel rod and double steel rod for your choose.

Features:

1. Transparent color make it easy to detect splice before shrinkage

2. Airproof structure keeping the splice point's good resistance of humidity and temperature

3. Strength member is made from "Full hard" stainless steel of 304 SUS and is ground at the edges before polishing to make it completely burr free to avoid rupturing during shrinking.

4. 304 SS rod offers better corrosion resistance, even in coastal environment. Resistant to heat shocks, no cracking dripping or flowing

5. Easily use and avoid any damages to the optical fiber during installation

6. Single holed(preshrunk) ends eliminates improper fiber threading

7. Smooth, rounded-end stainless steel reinforcing member ends decrease the risk of fiber damage during installation

8. Extended liner length prevents contact between the fiber and the backbone

9. Protect connection point, improve the mechanical strength, it is most reliable way to protect the fusion

10. Easy to operate, reducing the risk of fiber damage during installation

Technical Parameters:

|

Specification |

Test method |

Typical data |

|

Tensile strength(MPa) |

ASTM D 2671 |

18 |

|

Elongation at Break (%) |

ASTM D 2671 |

700 |

|

Density(g/cm2) |

ISO R1183D |

0.94 |

|

Dielectric strength (KV/mm) |

IEC 243 |

20 |

|

Permittivity |

IEC 243 |

2.5 |

|

Length rate of change (%) |

ASTM D 2671 |

+5 |

![]()