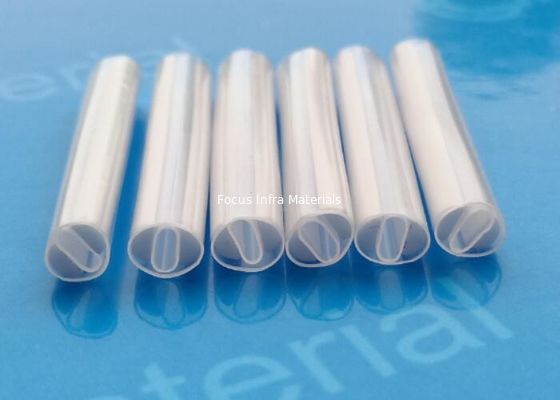

40mm 12F Heat Shrink Ribbon Fiber Splice Sleeve Protector For FTTH

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model Number | Ribbon Fiber Optic Fusion Splicing Proctor | Outer Tube Length | 40mm |

|---|---|---|---|

| Outer Tube Material | PE | Inner Tube Materials | EVA |

| Color | Clear | Use | FTTH |

| Packing | 50pcs/bag, According To Requirements | Size | 12F |

| Highlight | 40mm Ribbon Fiber Splice Sleeve,12F heat shrink splice protector,FTTH heat shrink splice protector |

||

Ribbon Fiber Optic Heat Shrink Sleeve Ceramic Fiber Optic Heat Shrink Sleeve 12F fiber splice protector

Description:

Ribbon Fiber Fiber Optic Protection Sleeve is designed for Ribbon fiber, normally it's 4 cores, 6 cores, 8 cores and 12 cores fiber optic protection sleeve for flat fiber cable.

Ribbon Fiber Fiber Optic Protection Sleeve is applied to the optical fiber closure to fix and protect the optical fiber when splicing. The sleeves can be divided into two types (single sleeve and ribbon sleeve) according to the function. The single type is used for the single-fiber, and the mass type is used for the ribbon fiber. It is different in the reinforcement between two types. The single one realizes the reinforcement by the stainless steel needles, the later one via the ceramic reinforcement member to realize the function. Ribbon sleeve means there are several cores for the fiber. So the mass sleeve includes 4cores, 6cores, 8cores, 12 cores (for types).

This product is constructed with an inner EVA meltable adhesive tube, a polyolefin heat shrink outer tube and either single or dual strength members. Our single strength member sleeve which has become an industry standard, has an after shrink diameter of 4.9 X 4.4 mm, and utilizes a special glass member.

Feature:

1. Single holed (preshrunk)ends eliminates improper fiber threading

2. Smooth, deburred stainless steel reinforcing member ends decrease the risk of fiber damage during installation.

3. Extended liner length prevents contact between the fiber and ther backbone

4. Clear sleeve design persign permits easy centering of splice before heating

5. Sealing structure makes the splice free from effect of temperature and humidity from environment

6. Protecting splicing point

7. Improve mechanical strength

8. Simple operation, reducing the risk of fiber damage during installation.

9. Does not affect the optical characteristics of the optical fiber.

10. Sealing structure to have good resistance of temperature and humidity performance

Applications:

1.Fusion splicing

2.Fiber cable protecting

3.FTTH system

4.Rack-mount & Wall-mount terminal box

5. Fiber Opitc Splice Closure

6. optical fiber switch box and so on continue protection