304 SUS Ribbon Fiber Splice Sleeve Protection For CWDM DWDM

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | 0.5mm 304SUS 20mm Length 250μm Bare Fiber Protection Heat Shrink Sleeves | Use | Fiber Fusion Splicing Protection |

|---|---|---|---|

| Brand | Focus Infra | Material | Heat Shrink Tube, 304 Stainless Steel Rod, Fusion Tube |

| Application | Optical Fiber Fusion Splicing, Protecting Optical Fiber Cable | Fit For | CWDM, DWDM Or More Smaller Application |

| Length | 20mm | Diamter Of Steel Rod | 0.5 Mm |

| Diameter After Shrink | 1.4 Mm | Steel Rod Pin | 1 |

| Color | Clear | Operating Temperation | -45°C To +120°C |

| Place Of Origin | China | Pack | 100pcs/bag Or 200pcs/bag |

| High Light | 304 SUS Ribbon Fiber Splice Sleeve,304 SUS splice protection sleeve CWDM,splice protection sleeve CWDM DWDM |

||

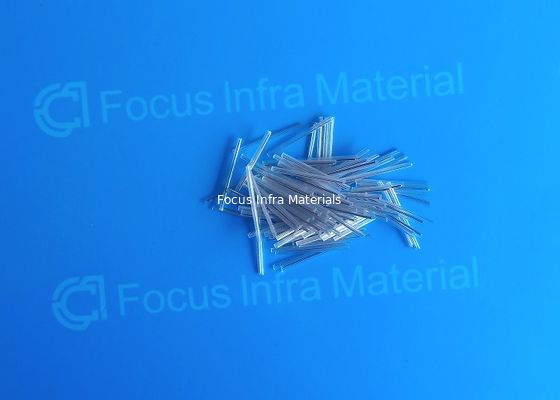

0.5mm 304SUS 20mm Length 250μm Bare Fiber Protection Heat Shrink Sleeves

Description:

The Fiber Protection Heat Shrink Sleeve is commonly known as an optical fiber heat shrink protect sleeve. It is a protective optical fiber splicing component composed of a special cross-linked polyolefin and a hot melt tube.

0.5mm 304SUS 20mm Length 250μm Bare Fiber Protection Heat Shrink Sleeves is designed for 250μm bare fiber splicing protection. Length is 20mm only, it is special used in smaller application, such as CWDM, DWDM ect. 0.5mm 304SUS 20mm Length 250μm Bare Fiber Protection Heat Shrink Sleeves is commonly known as an optical fiber heat shrink protect sleeve. 0.5mm 304SUS 20mm Length 250μm Bare Fiber Protection Heat Shrink Sleeves is widely used in communication optical fiber splicing projects, it is consisted of a special cross-linked polyolefin, a hot melt tube and a strengthen member.

0.5mm 304SUS 20mm Length 250μm Bare Fiber Protection Heat Shrink Sleeves is consist of 304 Stainless Steel Rod and EVA tubes. Its diameter is only about 1.4mm after shrink.

Product advantages:

1. Bare fiber hot melt, stainless steel needle, protect fiber

2. Industrial sealing treatment at both ends of the tube to ensure that the steel needle does not fall

3. Selected 304 high-quality stainless steel, not easy to rust, corrosion-resistant, and anti-aging

4. The double-layer shell is made of environmentally friendly PE and has a long service life

5. Better protection of bare fiber and prolong the service life of fiber

6. Protect connection point, improve the mechanical strength, it is most reliable way to protect the fusion

7. Easy to operate, reducing the risk of fiber damage during installation

8. Transparent tube, it is easy to see the status of spliced fiber connection

9. Min. shrinks temperature: 120 °C, shrink very fast and very easy to installation

10. Work temperature high (-55°C~100°C), widely used

Technical Parameters:

|

Specification |

Test method |

Typical data |

|

Tensile strength(MPa) |

ASTM D 2671 |

18 |

|

Elongation at Break (%) |

ASTM D 2671 |

700 |

|

Density(g/cm2) |

ISO R1183D |

0.94 |

|

Dielectric strength (KV/mm) |

IEC 243 |

20 |

|

Permittivity |

IEC 243 |

2.5 |

|

Length rate of change (%) |

ASTM D 2671 |

+5 |